travellerz71

Well-known member

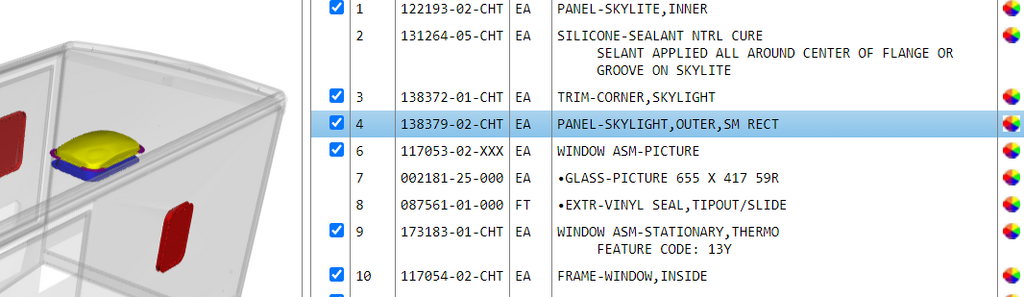

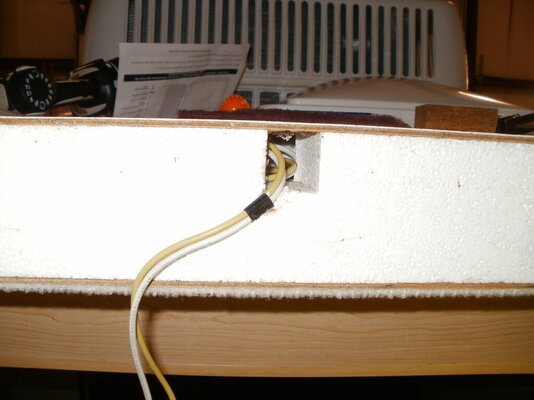

I am replacing the outer part of the skylight it has 4 trim corner pieces with 3 screws each. There are no screws on either of the long sides. Would it hurt to put screws on the sides and the ends and not use the trim pieces? I left out the part where I paid a rv repair to put the new one in. I am going to put butyl tape down under the skylight. They left the old sealer that was too hard to remove under the skylight and did not try to seal under it. They put Dicor self leveling on the outside over top of the old caulking that looks like silicone and of course it did not seal. Sorry for the rambling it is frustrating to pay someone and have to repair it myself.